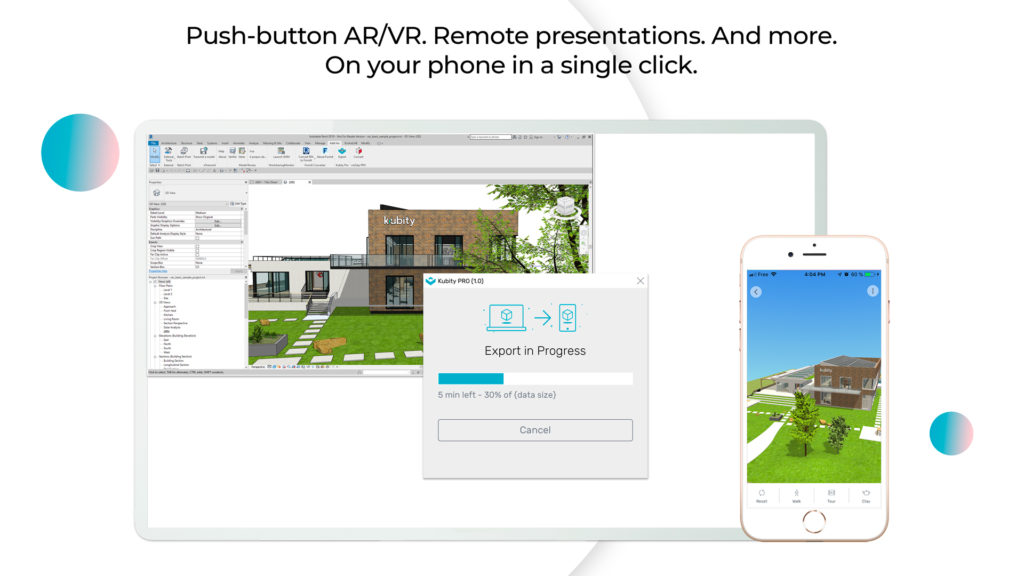

The structural engineer had called for a footing that extended out past the house, which wouldn’t work on that terrain.Įxploratory sketch of roof deck. One such area in this project was the lower right corner, where the ground dropped away sharply. And, in some spots, there might be issues that the engineer couldn’t have anticipated. It’s more streamlined for the engineers to stick to what they know best – calculations and safety margins. I suggested that thinking holistically would probably take longer. Thus, creating a virtual model of the building up front, can help in all sorts of ways during the actual build. By digitally constructing the building’s skeleton, especially when there is a lot of steel involved, the architect can assist with future steel shop drawings and explore questions of how things may come together in the field. The use of 3D visualization tools can help to forestall construction difficulties later on. The model could be spun around to see different aspects of the building, or to troubleshoot some parts of the design that are not coming together as they should. The digital models, together with Kubity, provided a set of tools that were easily transferable from one consultant to another, or even to the owner. The architect requested a wider beam in that spot, in order to ensure that the steel framing members matched as intended. The beams needed to be touching, for stability. The floors were actually about one and a half feet apart, with a short set of stairs between them. There was a gap of just a few inches between the beams, when they should be touching. In one spot, a purple beam for a higher floor plate didn’t come down all the way to meet the beam for a lower floor plate. The mobile version lets the user flip the model and zoom in on potential areas of concern. Using the Kubity app has helped identify problems and alignments that the structural engineer may not have been able to foresee. The 3D model showed that an unintentional 3.5-inch gap between the steel beams.

Image: Mark English ArchitectsĪt one corner, two floor plates come together, one higher than the other.

Interior stair framing, color-coded red for steel. Greg Corbett, Staff Architect at Mark English Architects in San Francisco, explained how one private home design needed refinement in order to reduce the amount of steel. Unless the architect specifies a framing type as part of the design, the structural engineer can choose the framing system – for example steel, wood, or reinforced concrete. The structural engineer is responsible for ensuring that the architect’s design has adequate framing to support the weight of the building. The architect didn’t want to pass unnecessary costs onto the client. In one project, a private home, the structural engineer chose to rely on steel – a safe structural choice.

In architectural design projects, structural engineers and other consultants make decisions based on the plans and the initial direction that they receive from the architect. Using 3D visualization tools and other methods, one design team worked out a cost saving of $220K without sacrificing the building’s structural integrity. By Rebecca Firestone | Editorials, Mark English Architects

0 kommentar(er)

0 kommentar(er)